What's wrong with

this clutch and flywheel?

(hope you don't have one of these in your car!)

Recently, we have

seen hybrid clutch options from some vendors.

This design consists of organic material on one side and a

segmented carbon or ceramic material on the other. The

idea is that the organic side will help smooth the

engagement, reducing the shuddering that one would expect

from the segmented side.

On generally accepted principle, any chain is only as strong

as the weakest link. With that in mind, temperature and

hp range of this hybrid clutch is identical to organic.

It would not matter if the carbon/ceramic side were more

durable, the entire assembly is subject to the limits of the

organic side. Therefore, no racing or slip-resistance

advantage at all. As carbon/ceramic side will wear

flywheel or pressure plate surface faster (even moreso in

traffic situations), there is a distinct disadvantage to this

setup.

Gimmick?

Quite likely. The "hybrid" design appears to

be more of a marketing hook rather than an actual performance

advantage. The brand we examined, although it still

functioned, was on the way to failure due to bad

design. Flexation of the underlying clutch disk caused

uneven wear of the carbon/ceramic pucks, and was not

sufficiently stiff to hold the solid organic side against the

pressure plate. While the underlying structural disk

might have been sufficient for a full-area friction material,

it clearly was not when built with the puck design.

Unless requested for "safety check" purposes, we

have kept the vendor of this setup anonymous. All

manufacturer markings have been blurred out

Ever wonder how to turn over $1000 worth of flywheel and

clutch in to scrap? Follow these steps...

| |

Click

any pic for a larger view.

|

Carbon/ceramic side of clutch

disk. Note individual pucks. These are

the friction areas on this side of the disk.

Note excessive scoring. This clutch was mated

to an aluminum flywheel with an inferior grade of

steel for the friction surface. The flywheel

vendor sold this clutch as a package with the

flywheel, quite obviously unaware of the material

characteristics. Note the scoring on the pucks. |

|

Another view of the pucks

showing scoring.

|

|

| Either inferior flywheel material or

flexation of the clutch disk caused dramatically

uneven wear of the flywheel. Note the

difference in material thickness between the inner

and outer diameter. With only 6,000 miles on

this clutch, it is doubtful that it would have

reached 10,000 miles before failing completely. |

|

| This is the "matched"

flywheel. Note the blue discoloration of the

friction surface's outer diameter from heat and

wear. A high-grade steel friction surface would

not have suffered this damage. Like all

aluminum flywheels, this unit has a steel plate

bolted to an aluminum disk. However, note the

placement of the 12 bolts. See that large areas

of the plate are not fastened. Under high heat,

this will allow the plate to buckle and lift,

decreasing contact area and causing abnormal

wear. That problem is also one possibility as

to why the inner and outer diameters are

"blued" with heat to different degrees.

|

|

| Close-up view of the friction

surface. Note the deep grooves. This

flywheel friction surface is beyond repair. |

|

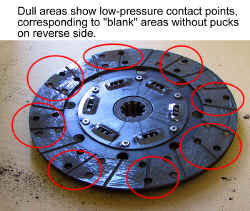

| This is the opposite side of the clutch

disk, the solid organic side. Note the

alternating shiny and dark areas, eight of

each. Not coincidentally, there are eight pucks

on the other side, whose positions correlate to the

shiny areas on this surface. What we see here is the

structural clutch disk plate flexing, causing the

dull areas to avoid contact with the pressure

plate. Effectively, only half of the organic

side was in contact, meaning the other half (the

shiny areas) were exposed to twice as much friction.

|

|

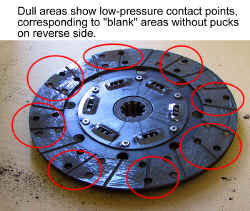

Same pic, circles mark the

areas that were not contacting.

|

|